Phone (02) 4964 9406

Mobile 0405 758 535

Email training@allclass.net.au

Address 10 Kilcoy Drive, Tomago NSW 2322

Working at heights is essential in numerous industries, from construction to maintenance. However, it also poses significant risks to the safety of workers. Safe Work Australia recorded 19 fatalities and 6,800 serious injuries due to falls from heights in 2022. The most serious and fatal falls are from roofs, ladders and scaffolding, even as low as four metres.

With these statistics in mind, developing a comprehensive working-at-height rescue plan to mitigate the risks is crucial. In this article, we provide advice for developing a working-at-height rescue plan and general education for workers at risk.

Note: these recommendations are general-purpose only. Please refer to Safe Work Australia, your employer or safety officer, and the relevant legislation in your state or territory, e.g. NSW Work Health & Safety Regulation 2017.

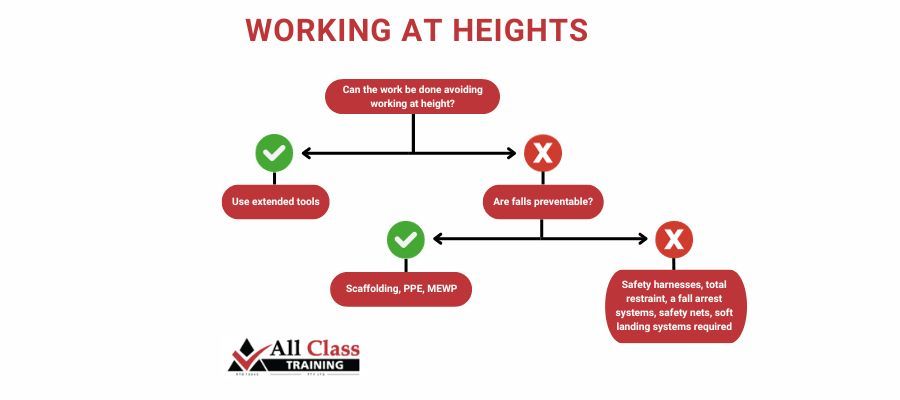

While the details can vary from state to state (or territory), the general consensus is that any workplace or person conducting business must manage the risks to health and safety associated with working at heights:

A working-at-heights rescue plan should consider all variables, including:

It’s important to remember that a rescue plan can be the difference between life and death, and the plan should be specific to the type of work, the work environment, the potential fall risks/hazards, and more.

The first step in developing an efficient working-at-height rescue plan is to complete a thorough risk assessment of the workplace. The goal is to:

Any new procedures should be tested regularly to ensure they are effective, and permanent anchor points should be inspected every 12 months by a competent, licensed person. Any temporary anchor points should be inspected before every use.

It’s important to note that your working-at-height rescue plan should also be adjusted depending on the workplace or location — if work occurs in various locations, the unique risks should be considered, and steps should be taken to reduce the risk of falls where reasonably practicable.

Ideally, a risk assessment should be completed before working at height, ensuring the relevant safety precautions and control measures are put in place to minimise the risk of accidents.

When developing a working-at-heights rescue plan, it’s imperative to keep the team up-to-date with the latest information, safety procedures, and training. This might include:

It is also crucial to ensure all team members who will be working at height are competent and professionally trained by a Registered Training Organisation (RTO) like All Class Training. We provide EWP and working-at-height training at our location in Tomago, just outside of Newcastle, NSW — our two-day training course will ensure all team members are safe and qualified to work at heights.

Communication is key when working at height, which means a competent spotter (or spotters) should be on-site at all times to watch over the work being completed and alert the person working above of any surrounding hazards or obstacles.

A spotter is a worker who communicates directly with the person working at heights and can raise the alarm in the event of an emergency. The spotter should always be visible to the person working above, even when using machinery.

If machinery (e.g. EWP) is in use, any movement should stop if the spotter is no longer in view.

EWP spotter requirements include:

As always, a risk assessment should be carried out before you decide to use spotters.

All Class Training offers working-at-height training in Tomago, a short drive from the Newcastle CBD in New South Wales. Students can complete their training over two short days, ultimately learning how to work safely in accordance with relevant legislation through theory and practical assessments.

We have a pass rate of more than 99% — book your working at height training at All Class Training today.